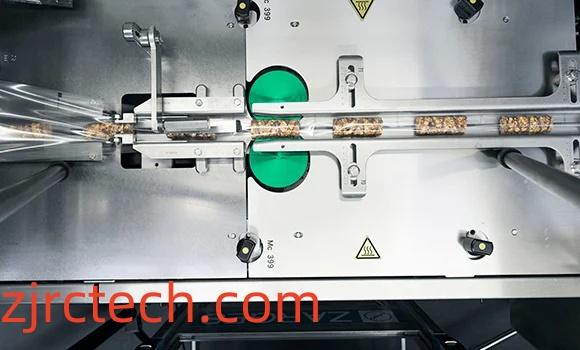

Rongchuang Advanced Food Machine Solutions For Flexible Food Processing

In modern food production, efficiency, consistency, and safety are paramount, which is why a Food Machine plays an essential role in large-scale operations. These machines automate repetitive tasks, maintain precise measurements, and optimize production flow, allowing manufacturers to meet stringent quality standards while reducing labor intensity. By adopting such technology, companies can enhance productivity and maintain high levels of hygiene.

One primary advantage of these systems is operational efficiency. Manual processing often introduces variability and slows production due to human limitations. Automated equipment streamlines workflows, allowing operators to focus on monitoring processes, inspecting outputs, and performing preventive maintenance. This not only accelerates production but also ensures that every batch meets the desired specifications, which is particularly important in industries like bakery, confectionery, and ready-to-eat meals.

Precision is another critical factor. Advanced machinery is designed to control ingredient proportions, mixing intensity, and processing temperatures accurately. Consistency in product quality reduces waste and enhances customer satisfaction, while also ensuring compliance with regulatory standards. For manufacturers, the ability to produce uniform products reliably is a significant competitive advantage.

Safety and hygiene are central concerns in food manufacturing. Machines constructed with stainless steel components and hygienic design features prevent contamination while simplifying cleaning procedures. Automated cleaning cycles, temperature controls, and enclosed processing areas protect both operators and consumers. Reducing human contact with raw materials also decreases the risk of contamination and supports compliance with industry safety regulations.

Flexibility is equally valuable. Modern machines are often modular and can handle multiple product types or recipes. Adjustable components allow manufacturers to switch production quickly, minimizing downtime and reducing the need for multiple specialized machines. This versatility not only saves costs but also supports innovation and responsiveness to market trends.

Energy efficiency is an increasingly important consideration. Intelligent systems monitor performance, optimize power usage, and minimize unnecessary energy consumption. This reduces operational costs and supports environmentally responsible production practices, which is vital in today's sustainability-focused industry.

Integration with digital monitoring tools further enhances the benefits of these machines. Sensors and automation allow real-time tracking of production parameters, enabling managers to make data-driven decisions, schedule maintenance proactively, and identify potential issues before they escalate. This ensures smooth operation and extends the equipment’s lifespan.

Investing in a high-quality food machine brings long-term advantages. Reduced labor, consistent product quality, enhanced safety, and energy efficiency all contribute to improved profitability. By combining durability, automation, and adaptability, such machines become indispensable in modern food manufacturing operations.

In conclusion, incorporating a Food Machine into industrial production enhances efficiency, precision, safety, and operational flexibility. For more information, visit https://www.zjrctech.com/product/.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness